Introduction to PV

Solar photovoltaic systems, commonly referred to as solar PV systems, convert sunlight directly into electricity. This is different to the solar thermal collectors for solar water heaters. A solar PV system can help reduce carbon emissions and your electricity bill by producing sustainable electricity from the sun instead of burning fossil fuels. WAH KOK offers a range of solar PV products to help you harness the power of the sun for commercial, industrial and residential electricity applications of all sizes.

Most electricity is distributed through an electrical utility provider, the company that produces and/or distributes electricity to consumers. The electricity from a variety of sources is distributed along the electrical grid and can span hundreds of miles from the power plants to homes and businesses. This grid network is not always reliable due to overloading, severe weather, and maintenance or upgrades. Installing a PV power system allows you to create your own electricity to supply your entire home or business and can potentially eliminate the issues associated with large utility grids. The amount of electricity generated is dependent on several factors: the size and arrangement of the PV power system, the PV module type, the available sunlight, and the efficiency of the electrical components used to covert solar energy into electricity usable by your home or building.

How PV Systems Work

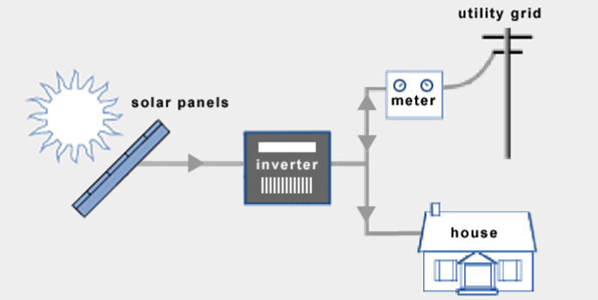

On Grid PV System

The grid-connected solar photovoltaic (PV) system is a common and cost-effective option to reduce electricity bills and emissions. It consists of PV modules, a grid-connect inverter, associated mounting hardware, and electrical cables and safety devices. You can generate your own renewable energy on site, and supplement your electricity needs from the local utility grid when the PV system is not supplying enough energy. You can also export excess electricity back to the utility company when the PV system is generating more electricity than you need during daylight hours. The way this exported electricity is metered and the rate of financial return varies by country, state, local district, and utility provider. The downside of this system configuration is that you are still connected to the grid. Depending on local regulations the system will automatically shut down if the grid becomes unavailable, meaning you will not produce any solar power during this time, and would still experience blackouts. You would also only use solar power during daylight hours with good solar irradiation, so at night and on cloudy days you would still draw power from the grid and pay an electricity bill.

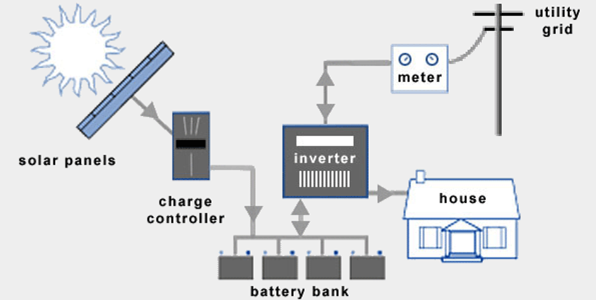

On Grid with batteries / hybrid PV system

A grid-connected photovoltaic (PV) system with batteries gives you the best of both worlds. The PV modules can be used to charge a battery bank during the day, and then provide this electricity to your home or business whenever it is needed (day or night). Maintaining a connection to the grid also allows for electricity to be supplied during periods of high use or when the weather is bad for extended periods. Depending on local regulations and government incentives, you may be able to export electricity from your battery bank at times when the utility provider needs it most, and attract a higher rate of return for that solar power. This system could also be configured to supply DC loads from the battery bank.

off grid PV system

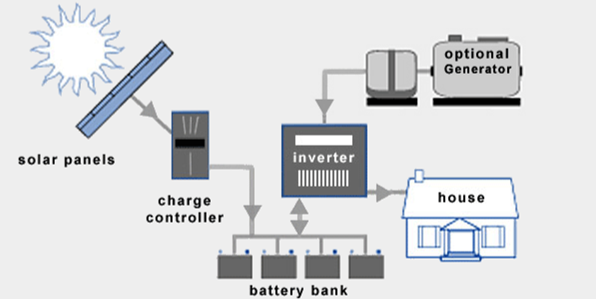

The off-grid solar photovoltaic (PV) system can be extensively applied in remote locations, and other areas not covered by the main power grid. The PV modules generate electricity that is used to charge batteries during sunlight hours. This can then power DC loads directly or be provided to the AC load through the inverter. This system configuration provides independence from the utility grid however there are limitations on the days of autonomy and the size of the loads that can be supplied by batteries and inverters on their own.

For some applications where small amounts of electricity are required, like emergency call boxes and UPS systems, PV systems are often cost justified even when the grid is accessible. When applications require larger amounts of electricity and are located away from existing power lines, PV systems can in many cases offer the least expensive and most viable option.

PV panel

To get effectively improved the rate of return on investment, WAH KOK selected the high efficiency PERC technology and latest half-cut technology can generate high efficiency and gain more power in low light environment.

Peak Power: 400-410WP

Features include:

72 monocrystalline solar cells comprised in series

Positive power tolerance of 0~+3% improves system performance

Industry-leading module efficiency: maximum efficiency of 20.36%

Tested up to 5400Pa for maximum load resistance

Verified resistance against PID effects

Progressive Power Warranty guarantees 80% of rated power at 25 years

Manufactured globally with world class quality standards

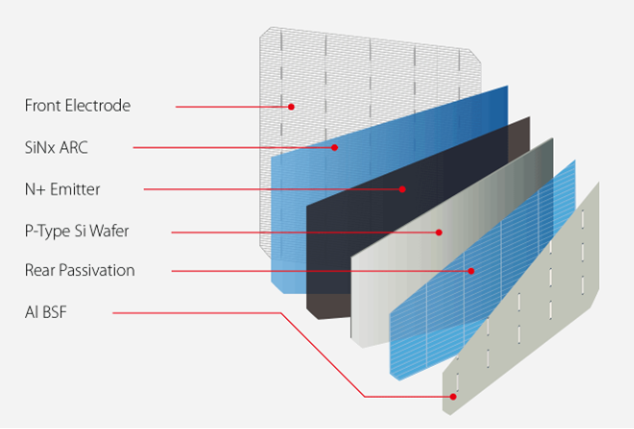

PERC Technology

The PERC cell has a passivated rear side and a laser grooving process, which significantly improves the cell efficiency.

Outstanding low irradiance performance, low power-temperature coefficient, low operating temperature, all these technologies lead to a high energy yield.

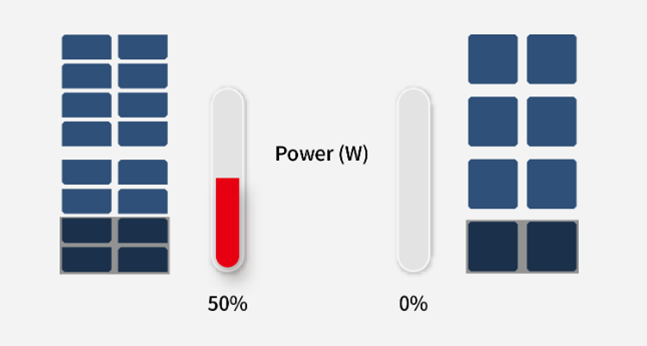

half-cut Technology

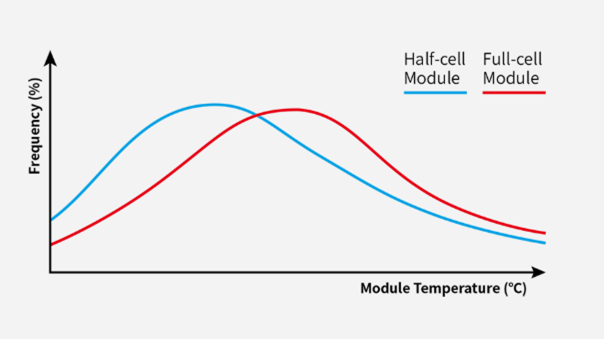

Half-cut cell technology is to cut the cell into two seperate parts by mature infrared laser, hence halve the working current. The thermal loss on the ribbon will be remarkably reduced and the module’s power increases by 2%. The reliability of module is also enhanced.

The combination of half-cut cell technology can amplify the gain over the effect of current-reduction.

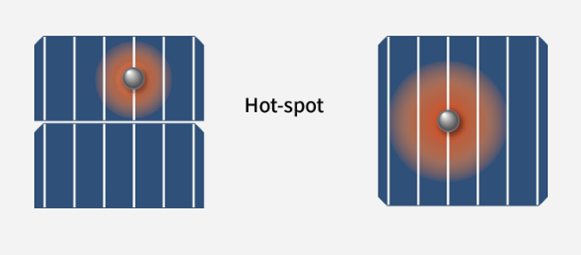

In field applications, small area shadings can cause the temperature of those parts extremely high. This phenomena is called hot spot. The long duration of hot spot could bring irreversible degradation of modules.

Because the string current of half-cell modules is half of full-cell modules, the hot spot temperature can be obviously reduced.

Half-cut cells have half of the working current, thereby the thermal loss is remarkably reduced. Operating temperature correspondingly decreases, and the reliability of module is improved as well as power gain.

Because of the unique parallel connection design, half-cell modules still have 50% power output under the circumstance of array shading in sunrise or sunset when portrait installation.

In addition, half-cut technology can improve the output of bifacial module under non-uniform incident illumination on the backside.

Inverter/Solar PV Technology

WAH KOK have several range of Solar PV Controller and Inverter from Residential (1.5KW) to Power Plant Application (3.4MW per controller). For Off-grid System can up to 78KW per controller integrated with inverter.

Batteries & Energy Storage Solution

For Residential or small factory to store electricity from PV power system, batteries will be needed. The batteries used for PV power systems are different from car batteries. The batteries best suited for use with PV power systems are called secondary or deep cycle batteries.

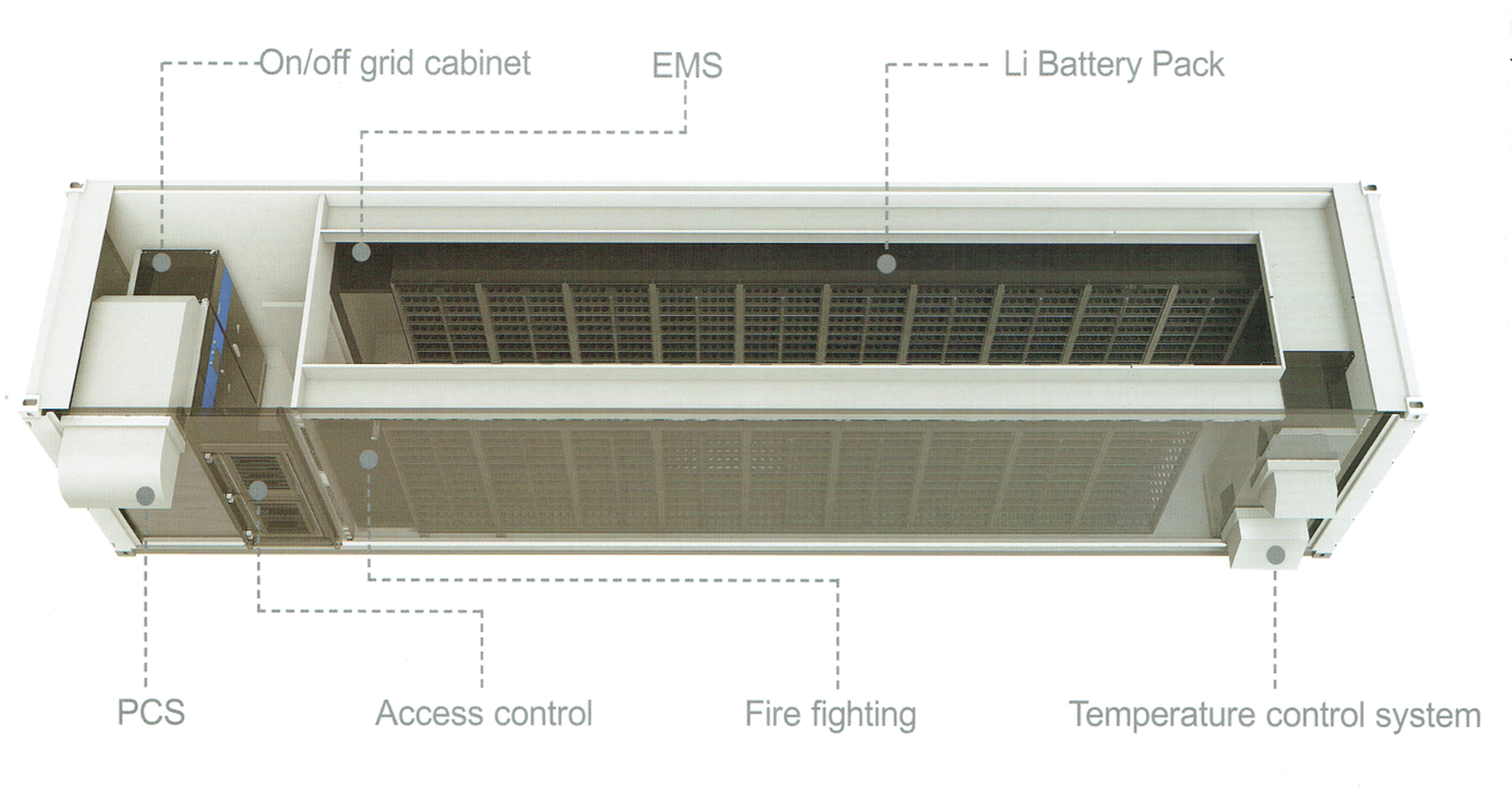

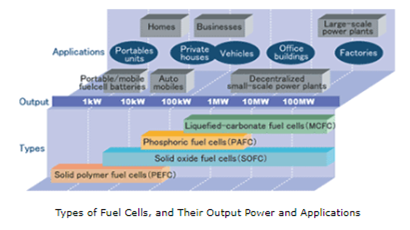

For Large scale factory, commercial and power plant, Wah Kok provide ready solution energy solution from 200KW to 3000KW per unit or customized design for difference application requirement, even Lithium-ion or Pb-C Battery Type Energy Solution.

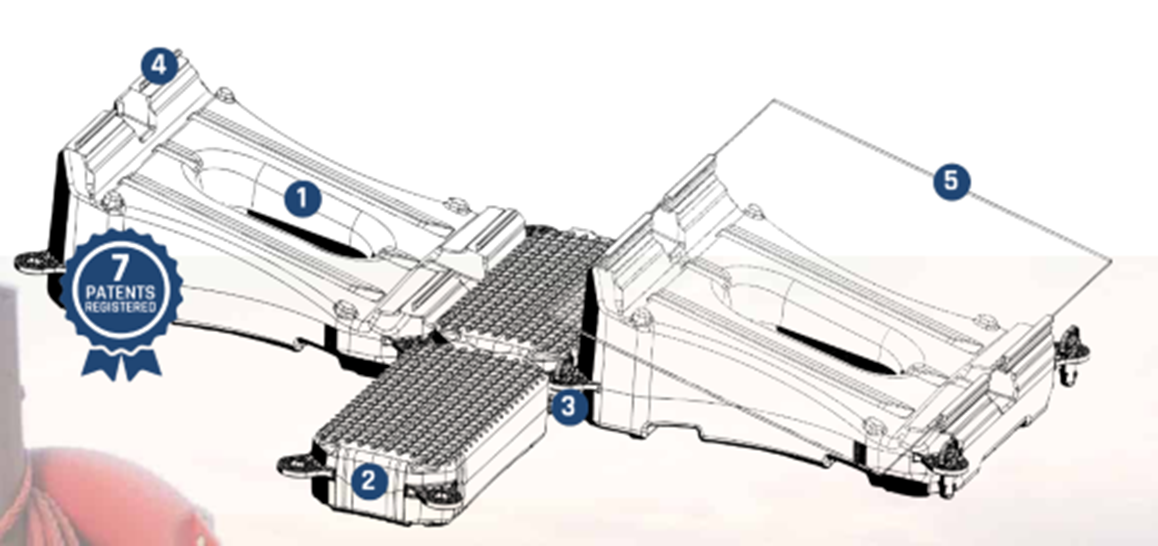

Floating Solar Solution

Quality is our priority, So that Wah Kok choose floating modular is a patented water-based PV concept – first fine tuned system to be industrialized – consisting of modular ‘lego-type’ floaters assembling into rows. Made from recyclable HDPE, the floating PV system enables to support PV modules above water while withstanding long-term environmental hazards, as wind, rain and snow.

To offer you the best experience with a long-lasting solution, our entire product range is qualified through technical tests for the reliability, performance and lifetime of your floating PV project. It’s comes standard with a 10-year warranty with the option to extend up to 25 years ensuring you a safe and bankable investment.

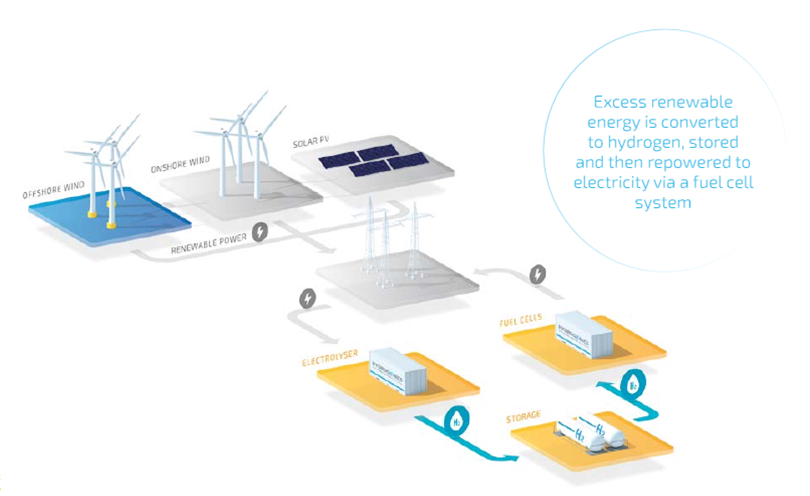

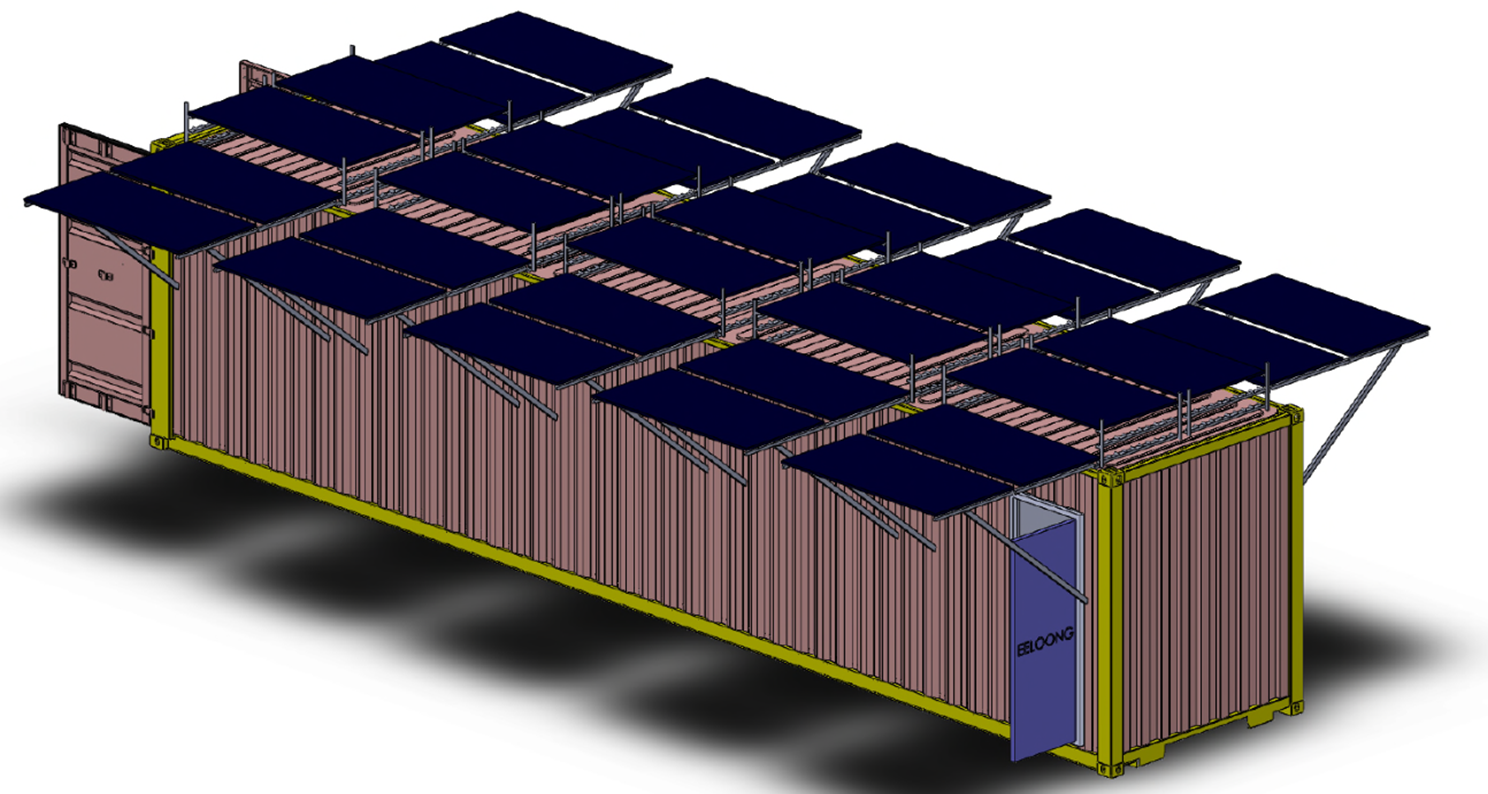

Hydrogen Fuel cell System

Why WAH KOK ?

WAH KOK and Strategy Partner are companies of engineers, designers, innovators and people who are focused on helping our customers with designing, manufacturing, building and installing industrial and commercial Hydrogen Systems. With our Solar PV energy system, Eeloong can provide reliable performance and reduced cost.

The Technology we can provide includes:

PEM and Alkaline Electrolyzer Hydrogen generators for:

Hydrogen generation for industrial processes,

Hydrogen generation for Fueling stations,

Hydrogen Energy storage and transportation. Currently, Hydrogenics is leading in “Power-to-Gas”: The world’s most innovative way to store and transport energy.

Hydrogen fuel cell power generators for:

Transportation such as trucks, urban transit buses, commercial fleets and utility vehicles

Stationary applications such for continuous and backup power for hospitals, emergency services, data centers, corporate and production facilities, telecommunication and small commercial buildings, Free standing electrical power plants and UPS systems (uninterruptible power supply)

What is Hydrogen Fuel Cell?

Hydrogen Fuel cells generate electricity quietly, efficiently, reliably, and with zero harmful emissions, for various applications. They are the cleanest and the most versatile power generating devices on the market. A Hydrogen fuel cell is an electrochemical device that converts the chemical energy of a fuel directly to usable electrical energy and some heat. The electricity is created electrochemically with hydrogen and an oxidizing agent, generally oxygen. When hydrogen is used as fuel, for example in a fuel cell electric vehicle, the only by-product is water.

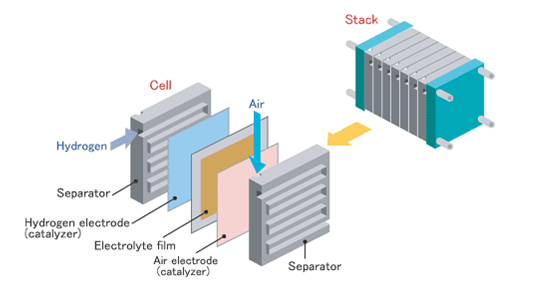

What are different types of fuel cells?

Similar to batteries and all other electrochemical cells, fuel cells have two electrodes, and an electrolyte sandwiched in between. Fuel cells are distinguished by the type of electrolyte they use. The more common fuel cells on the market are:

PEM “Polymer Exchange Membrane” also known as “Polymer Electrolyte Membrane” Fuel Cell (PEMFC)

“Solid Oxide” Fuel cell (SOFC),

“Molten Carbonate” Fuel cell (MCFC),

“Alkaline” Fuel Cell (AFC),

“Phosphoric Acid” fuel cell (PAFC).

“Direct Methanol” fuel cell (DMFC) is the only type of fuel cell that is distinguished by its fuel (Methanol) and not its electrolyte.

As above difference type of hydrogen fuel cell, Proton Exchange Membrane Fuel Cells / Polymer Electrolyte Fuel Cells (PEMFC/PEFC) uses a solid polymer membrane electrolyte that electrochemically reacts with hydrogen and oxygen to produce power. PEMFCs operate at relatively lower temperatures and pressures and deliver higher power densities compared to other fuel cells. They are also smaller and have lower weight and volume. PEMFCs contain no corrosive fluids and are the most versatile fuel cells suitable for a variety of mobility and stationary power applications. Due to their size flexibility, favorable power-to-weight ratio, and fast startup, they are the primary choice for vehicles such as cars, trucks, and buses.

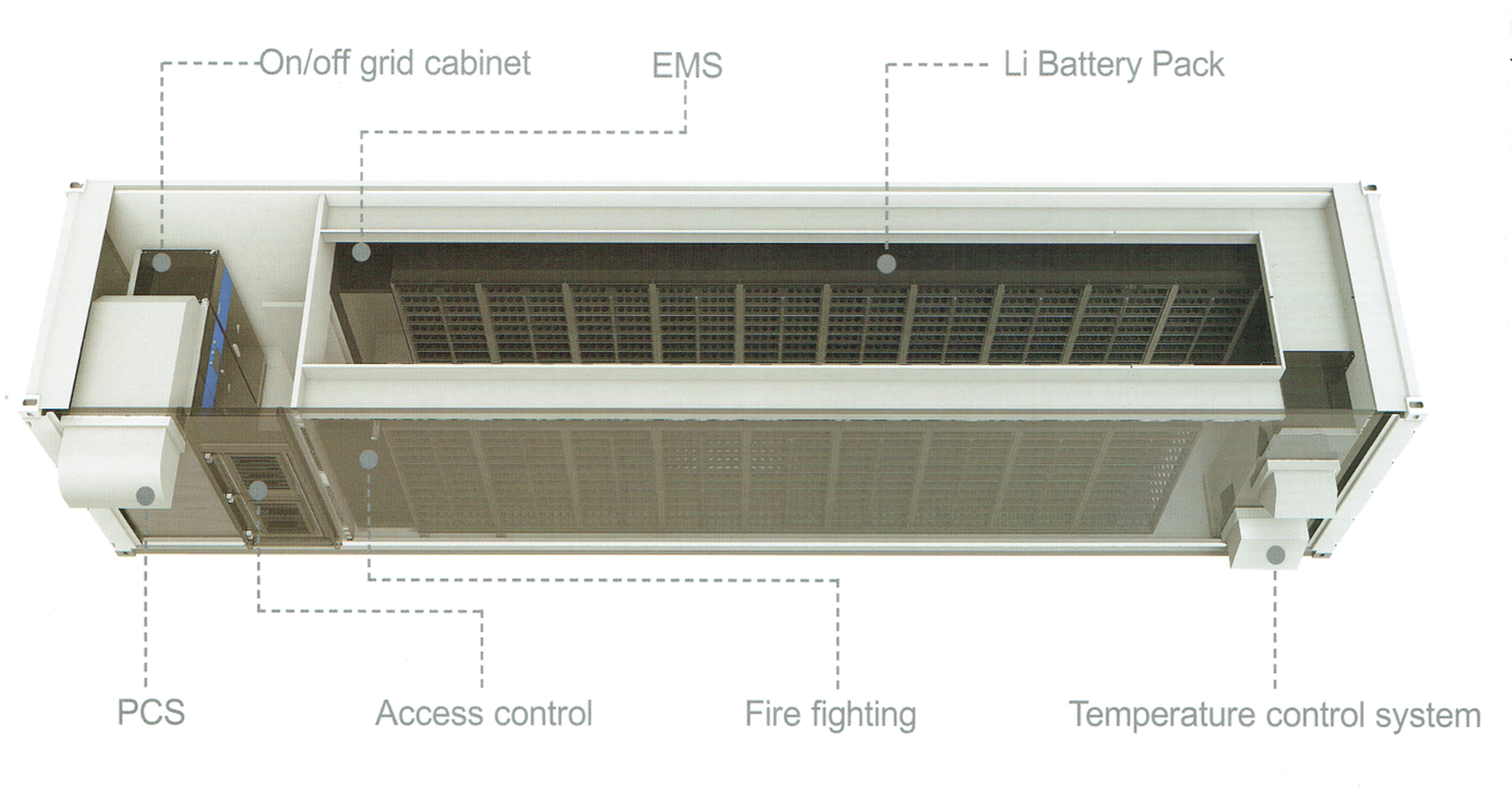

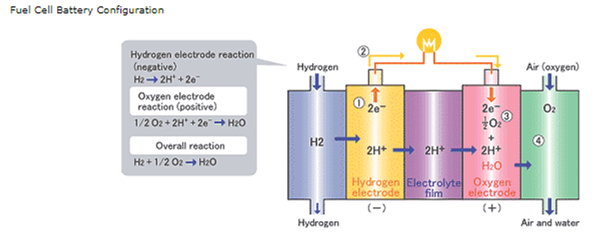

What does fuel cell works?

Hydrogen molecules (H2), supplied from outside, release two electrons (e-) and become hydrogen ions (H+).

The electrons from the hydrogen pass through the external circuit and flow to the oxygen electrode on the opposite side as current.Generation of Electricity

At the oxygen electrode, oxygen molecules (O2) from the air accept the electrons returned from the external circuit and become oxygen ions (O2-).

The oxygen ions combine with the hydrogen ions (2H+) passed through the electrolyte to form water (H2O).

What is an electrolyser?

An electrochemical device that uses electricity to split molecules into their constituent atoms. Thus electrolysers are widely used to split water into Hydrogen and Oxygen. Electrolysis is currently the most promising method of Hydrogen production with very high purities (99.999%), due to high efficiency and fast dynamic response compared to some other methods. Hydrogen made by electrolysis is extremely clean and can be put back into the grid or used in a fuel cell.

What are the different types of electrolysers?

Like fuel cells, electrolysers have two electrodes and an ion-conducting electrolyte sandwiched in between. They are distinguished by the type of electrolyte they utilize. There are a few different types of electrolysers that are currently used or under development. The two most common ones that are commercially used for Hydrogen production are:

Alkaline Electrolysers: These electrolysers use a liquid caustic electrolyte, usually ~%30 KOH. They use cheaper metals such as Nickel as catalyst and have a robust and reliable structure. Alkaline electrolysers produce Hydrogen with purity of 99.8%, operate at relatively low temperatures, and have a relatively high capacity. They typically operate at pressures of up to 30bars and low current densities.

Polymer Electrolyte Membrane (PEM) electrolyser: A PEM (Proton Exchange Membrane, or polymer Electrolyte Membrane) electrolyser utilizes a solid Polymer electrolyte membrane as the electrolyte. They are gaining increasing popularity for the following reasons:

1. Since there are no corrosive electrolytes in PEM electrolysers they are not susceptible to leakage. Therefore maintenance costs are reduced.

2. They are able to operate at higher pressures and high current densities. This is especially useful for systems working with dynamic energy sources such as wind and solar to capture spikes in the input energy. Therefore they are the better alternative for energy storage systems connected to renewable energy sources.

how does an electrolyser work?

An electrolyser uses an ionically conductive solid polymer. When potential difference (voltage) applied between the two electrodes, negatively charged Oxygen in the water molecules give up their electron at the anode to make protons, electrons, and O2 at the anode. The H+ ions travel through the proton conducting polymer towards the cathode where they take an electron and become neutral H atoms which combine to make H2 at the cathode. The electrolyte and two electrodes are sandwiched between two bipolar plates. The role of bipolar plate is to transport water to the plates, transport product gases away from the cell, conduct electricity, and circulate a coolant fluid to cool down the process.

Same as fuel cells, many electrolyser single cells may be connected in series to make the core component of an electrolyser system, the cell stack, where both Hydrogen and Oxygen are produced.

key facts on hydrogen?

Hydrogen is Life

Hydrogen is the most common element around us. It makes up to 75% of the mass of entire universe, in molecular forms such as water and organic compounds.

Hydrogen is the lightest and simplest element with the chemical symbol H and atomic number 1. It consists of only one electron and on proton.

Hydrogen is a gas (H₂) at standard temperature and pressure, which can be compressed or liquefied if needed.

Hydrogen is carbon-free, exceptionally clean, lighter than air, odourless and non-toxic.

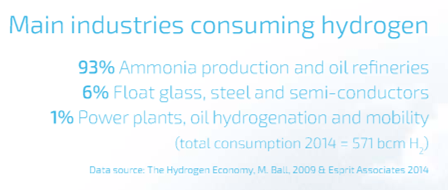

Hydrogen is Widely Used

Hydrogen is safe to produce, store and transport.

Hydrogen has been safely used for many decades in a wide range of industrial applications:

– In chemical Plants

– In industrial manufacturing

– In Power Plants

– In the food industry for the hydrogenation of oils

There is growing use of hydrogen in mobility for fuel cell electric vehicles (FCEV)

hydrogen solutions for a renewable based energy system

Hydrogen produced from renewable power via water electrolysis can be used to reduce carbon emissions further in the power, gas, industry, fuel and mobility sectors, for a cleaner and more sustainable future. It’s can split to:

Power to power

Power to gas